Edit Content

The DBB-SAVER is used when maintenance work must be executed on a piece of equipment, whilst bordering installation parts remain pressurized and available for operations.

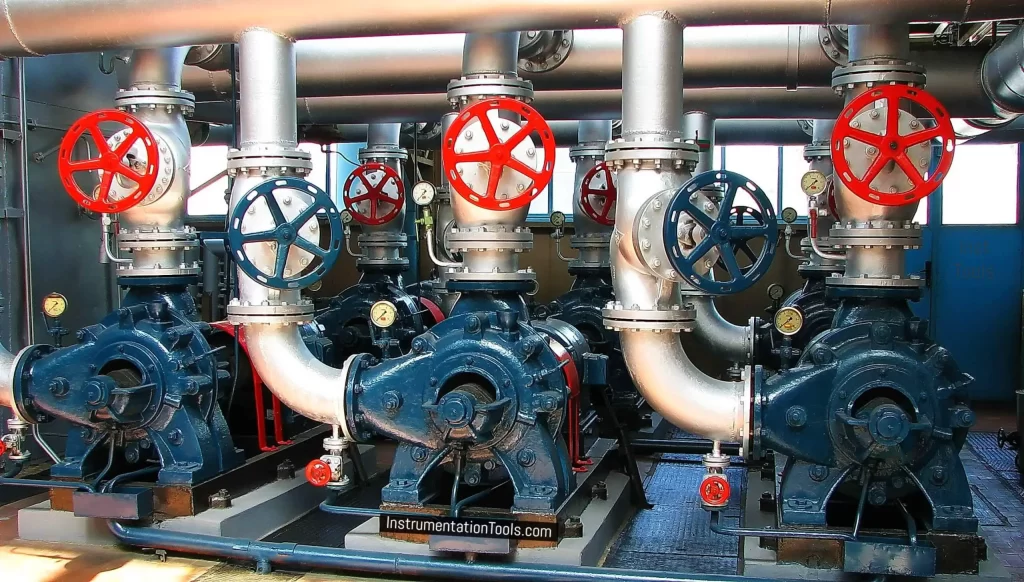

This piece of equipment must be isolated. This is done by valves. Sometimes, valves are only the initial isolation, which makes it possible to safely place blind flanges afterwards.

Either when working on the equipment directly behind the isolation valves or when placing a blind flange, the isolation valves should not have a leak rate beyond the companies pre-defined standards to ensure a safe working place. In case of explosive and/or toxic media the standard is often tight shut off (TSO), which means zero leakage.

Safe sequence control of valves |Rupture and bursting discs | Onstream Pipe Inspection and Remediation | Fugitive Emission Inspection and Flare Leaks Detection.